Principles and innovative value of single-sided flower burning technology

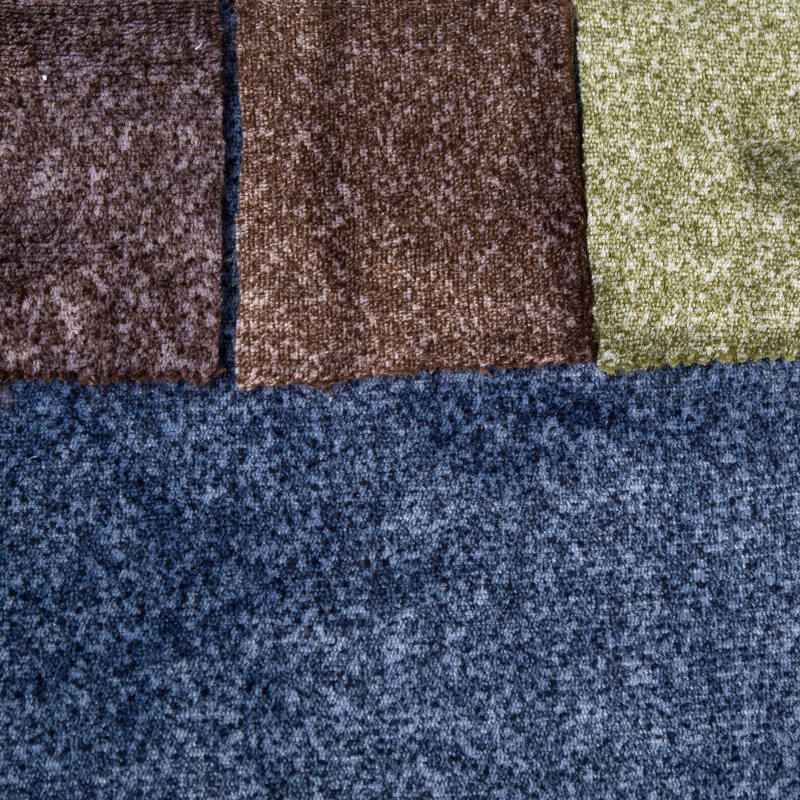

Single-sided burning technology is a process that selectively removes some fibers on blended fabrics through chemical corrosion or laser burning. Crystal Super Soft Fabric Factory Usually uses polyester-cotton or polyester-viscosity-blended base fabrics, which use acid agents or hot melt principles to dissolve cellulose fibers (such as cotton or viscose) to retain the polyester fibers to form three-dimensional and hollow patterns. Compared with traditional double-sided flowering, the single-sided process only forms a pattern on one side of the fabric and maintains a complete structure on the other side, which not only ensures the exquisiteness of the flower shape, but also maintains the basic strength of the fabric.

The core advantage of this technology lies in the creation of three-dimensional texture. Crystal Super Soft FabricCrystal Super Soft FabricCrystal Super Soft Fabric has a subtle light transmission and tactile layer through the contrast between the burning area and the non-burning area, while greatly improving breathability. In high-end home clothing, curtains and bedding applications, this "transparent but not exposed" visual effect significantly increases the added value of the product.

Key controls on raw material selection and pretreatment

To achieve the ideal flower burning effect, Crystal Super Soft Fabric Factory has strict requirements on raw material ratios. Usually, a blended combination of 70% polyester + 30% cotton or 50% polyester + 50% viscose is used to ensure that the acid etching reaction only acts on the cellulose component. The factory's quality inspection department will conduct infrared spectroscopy analysis of the yarn to verify the accuracy of the fiber composition and avoid uneven burning caused by raw material deviation.

During the weaving stage, Crystal Super Soft Fabric needs to use high-density plain or twill tissue to provide a stable structural basis for subsequent flowering. Some factories will pre-polish bioenzymes to reduce the hairy surface of the fabric and make the edges of the burning pattern clearer and sharper. Although these pretreatment processes increase costs, they can significantly increase the first-grade yield of the finished product.

Process decomposition of precision flower burning process

Crystal Super Soft Fabric Factory’s single-sided flowering production line includes three core links: flower positioning, corrosion control and neutralization and cleaning. First, the pattern containing sodium bisulfate or acid paste is accurately applied to the single side of the fabric through a CNC printing machine. This process requires the environmental humidity to be controlled at 60%±5% to prevent the paste from penetrating and diffusion.

When entering the evaporation stage, the control of temperature and time directly determines the depth of the burning. The leading factory adopts a segmented temperature-controlled steamer, which activates chemical reactions at 110°C in the initial stage, and then drops to 90°C to delay the reaction speed, achieving an accurate corrosion depth of 0.1-0.3mm. After the corrosion is completed, the fabric needs to enter multiple water washing tanks immediately, and add sodium carbonate to neutralize residual acid. The water quality in this link must meet the soft water standard to prevent the reaction of calcium and magnesium ions and acidic substances to form water stains.

The key to texture improvement of finishing technology

The strength of the fabric will be partially reduced after burning, and Crystal Super Soft Fabric Factory makes up for this defect through innovative post-organization processes. The low-tension airflow soft machine is used for fluffy treatment, so that the polyester fiber in the burning area naturally stretches to form a micro-velvet feeling. Some high-end products will also be sorted in silicone oil microcapsules to form a nano-level protective film on the surface of the fiber, which not only maintains a super soft touch, but also improves the fabric's anti-pilling performance.

In the finalization process, the factory adopts an infrared synchronous monitoring system to adjust the cloth surface tension in real time to prevent the deformation of the burning pattern. It is worth noting that some Crystal Super Soft Fabric products will be combined with transparent UV coating, which will increase sun protection while retaining light transmission, expanding the application scenarios of outdoor household products.

Special requirements of quality inspection system

Due to the particularity of the flowering process, Crystal Super Soft Fabric Factory has established quality standards that are different from conventional fabrics. In addition to the conventional color fastness and shrinkage tests, three special inspections are also required: the flower pattern accuracy is compared with the design draft with an industrial CCD camera, allowing tolerance to not exceed 0.3mm; the transmittance uniformity is measured by a spectrophotometer, requiring the transmittance deviation of each area to be ≤5%; the intensity test focuses on the junction between the burning and non-burning areas to ensure that the tearing strength is not less than 60% of the original fabric.

The factory laboratory also simulates actual use scenarios, conducts 5,000 friction tests to verify the durability of the pattern, and pH skin contact safety tests. Only Crystal Super Soft Fabric that passes all 23 tests can obtain the factory's quality certification label.

Market Application and Consumer Value Creation

Crystal Super Soft Fabric, which uses single-sided flowering technology, is reconstructing the high-end textile market structure. In the home field, the summer quilt made of this fabric can not only ensure breathability, but also enhance the beauty of the bedroom through exquisite patterns; in the clothing industry, the clever combination of the burning parts and the solid color areas creates a "second layer of skin"-like wearing experience, which is very popular among light luxury brands.

Crystal Super Soft Fabric Factory's research data shows that the premium space for products using Shaohua technology can reach 30-50%, and the customer repurchase rate is increased by 40%. This is mainly attributed to the differentiated value it creates: it maintains super soft features tactile, visually presents a high-end customization, and functions to take into account both breathability and moderate shading.

Technical development trends and environmental protection upgrades

The forward-looking Crystal Super Soft Fabric Factory has begun to lay out a new generation of flower-burning technology. The introduction of laser flowering equipment has increased the pattern accuracy to 0.05mm level, while reducing wastewater discharge by 90%; the directed degradation technology of biological enzymes has genetically modified cellulase to achieve a more environmentally friendly fiber removal process.

In terms of sustainability, leading factories have begun using recycled polyester as base cloth material and have developed closed-loop water treatment systems to reduce water consumption per meter of fabric from traditional 50 liters to 12 liters. These innovations not only meet the requirements of the EU's green new policy, but also provide brands with strong environmentally friendly marketing support points.

The breakthrough in single-sided flowering technology demonstrates the innovative capabilities of Crystal Super Soft Fabric Factory in the field of high-end functional fabrics. By precisely controlling the corrosion depth, optimizing the post-organization process and establishing a strict quality inspection system, the factory has successfully integrated artistic beauty and practical functions into the fabric genes. As consumers continue to upgrade their requirements for personalization and comfort in textiles, the Crystal Super Soft Fabric suppliers that master the core flowering process will surely occupy the commanding heights of the value chain.

For brands, choosing the Crystal Super Soft Fabric Factory cooperation with a complete flower-burning technology system is not only a guarantee of quality, but also a strategic choice for product differentiation. In the future, with the application of digital twin technology in flower design and the continuous iteration of environmentally friendly processes, single-sided flowering technology is expected to become the standard configuration in the high-end fabric market, redefining the quality connotation of "super soft".

English

English Español

Español 中文简体

中文简体