Introduction to Dyeing Printing Knitted Fabrics

The global textile industry continues to evolve with Dyeing Printing Knitted Fabrics remaining at the forefront of innovation. This specialized process combines color application and pattern creation on stretchable knit materials, presenting unique technical challenges and opportunities. Manufacturers specializing in Dyeing Printing Knitted Fabrics must balance aesthetic requirements with functional performance across various applications.

Technical Process of Dyeing Printing Knitted Fabrics

The production of Dyeing Printing Knitted Fabrics requires specialized equipment and expertise. Unlike woven textiles, the elastic nature of knits demands modified approaches to ensure color fastness and pattern integrity. Modern facilities processing Dyeing Printing Knitted Fabrics utilize computerized systems to maintain consistent quality while accommodating the fabric's natural stretch characteristics.

Material Considerations for Dyeing Printing Knitted Fabrics

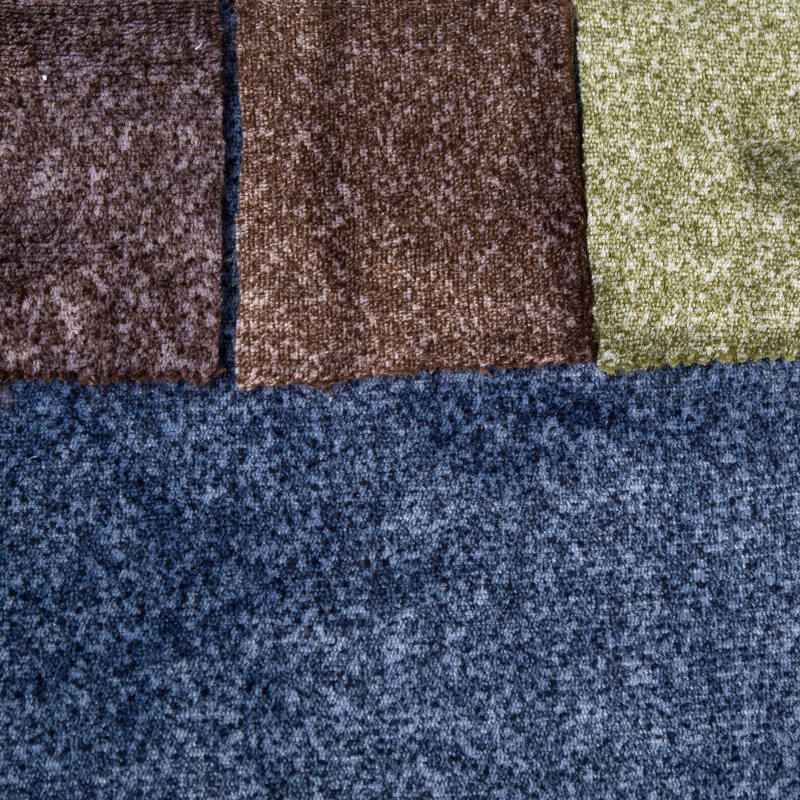

Successful Dyeing Printing Knitted Fabrics production begins with proper fiber selection. Cotton, polyester, and blended yarns each respond differently during the Dyeing Printing Knitted Fabrics process. The growing demand for sustainable options has led to innovations in organic cotton and recycled polyester Dyeing Printing Knitted Fabrics that maintain performance while reducing environmental impact.

Innovative Techniques in Dyeing Printing Knitted Fabrics

Recent advancements in Dyeing Printing Knitted Fabrics include digital printing systems specifically designed for knit structures. These technologies allow for more precise application when creating Dyeing Printing Knitted Fabrics with complex patterns. Waterless dyeing methods are also gaining traction in the Dyeing Printing Knitted Fabrics sector, significantly reducing the industry's water footprint.

Quality Standards for Dyeing Printing Knitted Fabrics

The evaluation of Dyeing Printing Knitted Fabrics includes rigorous testing for color fastness, stretch recovery, and durability. Industry certifications for Dyeing Printing Knitted Fabrics now encompass both performance metrics and sustainable production practices. Manufacturers investing in Dyeing Printing Knitted Fabrics must comply with increasingly strict international regulations.

Market Applications of Dyeing Printing Knitted Fabrics

Dyeing Printing Knitted Fabrics serve diverse markets from fashion to technical textiles. The activewear sector particularly benefits from advanced Dyeing Printing Knitted Fabrics that combine moisture management with vibrant designs. Medical applications of Dyeing Printing Knitted Fabrics continue to expand with the development of antimicrobial treatments.

Sustainability Challenges in Dyeing Printing Knitted Fabrics

The environmental impact of Dyeing Printing Knitted Fabrics production remains a key industry focus. New technologies for Dyeing Printing Knitted Fabrics aim to reduce chemical usage while maintaining color vibrancy. Closed-loop systems for Dyeing Printing Knitted Fabrics are becoming more prevalent as manufacturers seek to minimize waste.

Future Trends in Dyeing Printing Knitted Fabrics

The next generation of Dyeing Printing Knitted Fabrics will likely incorporate smart technology integrations. Research in Dyeing Printing Knitted Fabrics includes temperature-responsive colors and embedded sensors. These innovations will expand the functional possibilities of Dyeing Printing Knitted Fabrics beyond traditional applications.

English

English Español

Español 中文简体

中文简体