In the textile industry, the strength of a product often lies in a single defining characteristic. For polycotton terry cloth factory operations, absorbency is the feature that sets this fabric apart. The unique looped structure combined with a balanced polycotton blend provides exceptional water retention while ensuring durability and comfort. As demand for versatile fabrics continues to grow, absorbency becomes not only a technical specification but also a driving force shaping manufacturing trends.

The Structural Basis of Absorbency

Polycotton terry cloth is produced by weaving or knitting loops on the surface of a polycotton base. This construction significantly increases the surface area, allowing the fabric to retain liquid far beyond what flat textiles can achieve. A polycotton terry cloth manufacturer focuses on loop density, fiber composition, and finishing techniques to maximize absorbency without compromising fabric strength.

Unlike pure cotton terry, the polycotton blend introduces polyester fibers that enhance resilience while maintaining comfort. This balance is essential for wholesale polycotton terry towel fabric and industrial cleaning materials, where repeated washing and heavy use are common.

Why Absorbency Matters in Diverse Applications

Absorbency determines the suitability of polycotton terry cloth across industries. In personal care, it ensures effective drying in bath towels. In professional environments, absorbent polycotton terry cloth for kitchen use or industrial cleaning guarantees efficiency and reliability. Even in apparel, sportswear made from absorbent terry fabric supports moisture management.

The flexibility of this characteristic explains why custom polycotton terry cloth production line investments often prioritize absorbency testing. Manufacturers understand that consistent performance in this aspect directly influences product acceptance in global markets.

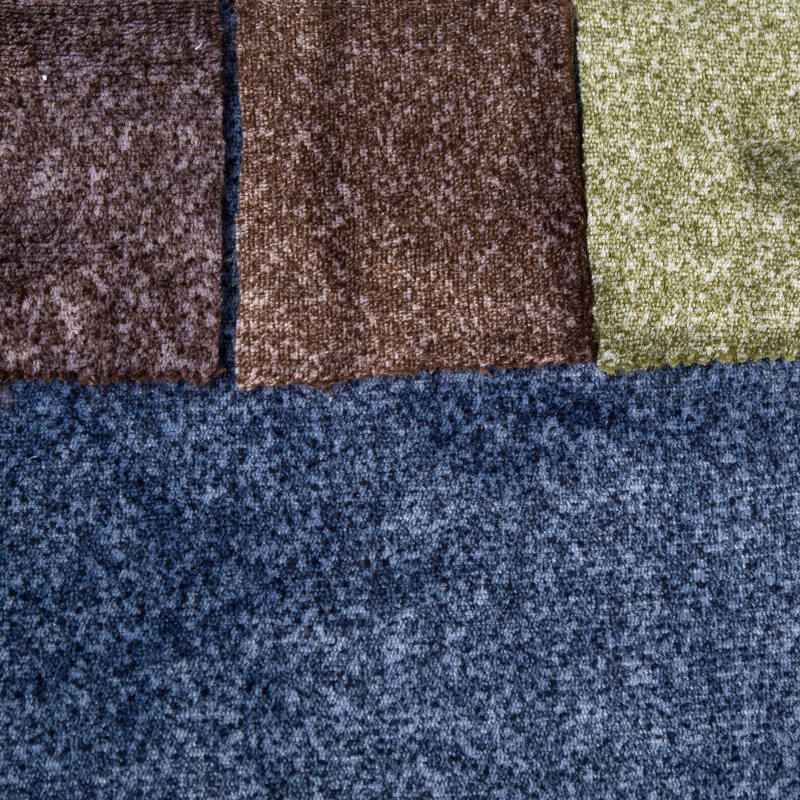

Comparative Features of Polycotton Terry Cloth

To better understand how absorbency integrates with other qualities, the following table highlights comparative attributes typically evaluated by a polycotton terry cloth factory.

| Feature | Role in Production | Impact on Application |

|---|---|---|

| Absorbency | Retains moisture through looped structure | Essential for towels, cleaning cloths, and sportswear |

| Durability | Enhanced by polyester content | Extends lifespan in industrial and household use |

| Comfort | Cotton softness balanced with polyester | Suitable for garments and personal textiles |

| Easy Care | Resistant to shrinking and wrinkling | Maintains quality after multiple washes |

| Cost Efficiency | Balance between cotton and polyester pricing | Competitive edge in wholesale polycotton terry cloth |

The Role of Absorbency in Factory Production Strategies

In a polycotton terry cloth factory, production strategies often revolve around controlling absorbency through precise technical adjustments. Loop length, yarn twist, and finishing processes are key variables. For instance, a shorter loop may reduce softness but enhance liquid retention. Similarly, finishing treatments can optimize quick-dry properties while sustaining absorption levels.

Factories producing polycotton terry cloth for garments or upholstery frequently tailor absorbency to match end-use requirements. For cleaning fabrics, high absorbency is prioritized. For upholstery, moderate absorption with greater durability may be more desirable. This adaptability underscores the central role absorbency plays in design decisions.

Absorbency as a Market Driver

The wholesale polycotton terry cloth market is influenced by buyer expectations around absorbency. Retailers and distributors often select suppliers based on demonstrated performance in water retention and consistency across batches. As eco-friendly polycotton terry cloth factory operations gain traction, absorbency testing is also being linked with sustainable finishing techniques that reduce chemical usage without diminishing fabric performance.

For bulk buyers, such as those sourcing polycotton terry cloth fabric for cleaning cloths or sportswear, assurance of high absorbency ensures reliability in downstream applications. This makes absorbency not only a technical characteristic but also a commercial asset.

Innovation and Future Outlook

Absorbency remains the defining feature guiding innovation in polycotton terry cloth production. Emerging technologies such as advanced loop weaving and eco-friendly finishes are enhancing liquid retention while reducing environmental impact. The demand for absorbent polycotton terry cloth for bath towels factory supply continues to rise, and suppliers are expected to invest in refining absorbency as a competitive differentiator.

At the same time, industrial polycotton terry cloth manufacturer initiatives are exploring hybrid blends that integrate recycled fibers without reducing absorption. These developments point to a future where absorbency will remain the benchmark for quality, sustainability, and performance in polycotton terry cloth.

Conclusion

The story of polycotton terry cloth factory production can be told through a single defining feature: absorbency. From its structural foundation to its role in diverse applications, absorbency influences how fabrics are manufactured, marketed, and consumed. It supports the growth of wholesale polycotton terry towel fabric, drives innovation in eco-friendly production, and ensures reliability in industries from personal care to industrial cleaning.

English

English Español

Español 中文简体

中文简体